Tel: 0086-10-58693398

Fax: 0086-10-58693594

E-mail: byjck@byjc.com.cn

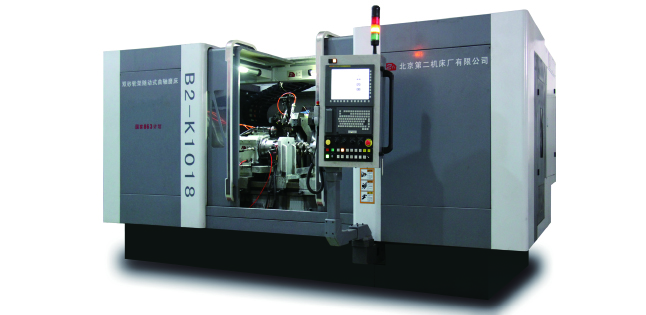

B2-K1018 Gouble Wheel Head Follow-up CNC Crankshaft Grinding Machine is aplies the advanced technology of follow-up swing type grinding rod journal, and by means of CNC linkage between two grinding wheel feed

axes (X1 and X2 axis) and workpiece rotation axes (C1 and C2 axis) as well as on-line measurement under full closed loop control, synchronous grinding of rod journals with different phases, one main journal and one crankpin or two main journals on crankshaft can be realized, thus thoroughly resolved the weakness of poor flexibility and complicated adjusting on the traditional eccentric clamp type crankshaft grinding machine. The machine tool is capable of one-time clamping to ensure the accurate processing of the crankpin, main journal and thrust surface of the crankshaft. The machine features on easy operating, reliable capacity and high machining precision.

| ITEM | UNIT | B2-K1018 | |

| Max. swiveling diameter | mm | Φ520 | |

| Distance between Centers | mm | 600/1200 | |

| Height of center | mm | 350 | |

| Max. workpiece weight between centers | kg | 150 | |

| Control System | FANUC / SIEMENS | ||

| Grinding wheel (Max.) | OD×W×ID | mm | Φ650×( 16 - 80 ) (CBN) |

| Linear speed | mm/sec | 120 | |

| Wheel head (X axis) | Total travel | mm | 400 |

| Feed speed | mm/min | 0.01 - 60000 | |

| Minimum setting unit | mm | 0.0001 | |

Backward lower sliding table (Z axis) | Type | Backward longitudinal movement | |

| Feed speed | mm/min | 0.02 - 20000 | |

| Minimum setting unit | mm | 0.001 | |

| Work head | Center | Special purpose chuck | |

| Rotating speed | r/min | 0 - 200(stepless) | |

| Tailstock | Center | Special purpose chuck | |

| Rotating speed | r/min | 0 - 200(stepless) | |

| Travel of center | mm | 100 | |

| Electrical system | Power of wheel spindle motor | kw | ~30 |

| Feeding of wheel head | Linear motor | ||

| Feeding of backward sliding table | N.m | 30 | |

| Total power | kw | ~160 | |

| Net weight | kg | ~25000 | |